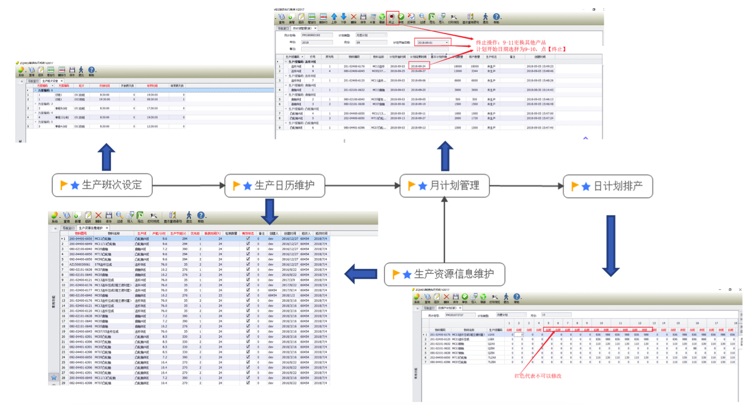

Realize multi-variety planning and scheduling based on limited capacity

Implement production plan to pull material demand and drive product delivery logistics

Accurate planning and scheduling optimize the utilization of manufacturing resources

The production planning, execution and feedback form a business closed loop to realize lean management

Equipment static comprehensive management, complete the whole process control of equipment classification management - finding problems - joining the regular inspection plan - maintenance workers single pool

Improve the health of equipment, complete the new leap in equipment utilization under the precise planning schedule

Equipment interconnection, clear grasp of equipment running status, management work targeted

Build a complete equipment management knowledge system to form a knowledge base

Rapid modeling, comparison, analysis, according to the actual needs of the enterprise for each dimension of quality analysis

Real-time quality related data acquisition, automatic generation of quality analysis report

The whole life cycle quality management of "raw material quality - production process quality - finished product quality - after-sales quality"

Improve the speed of business response, improve the collaboration relationship between businesses, and prevent non-compliance transactions

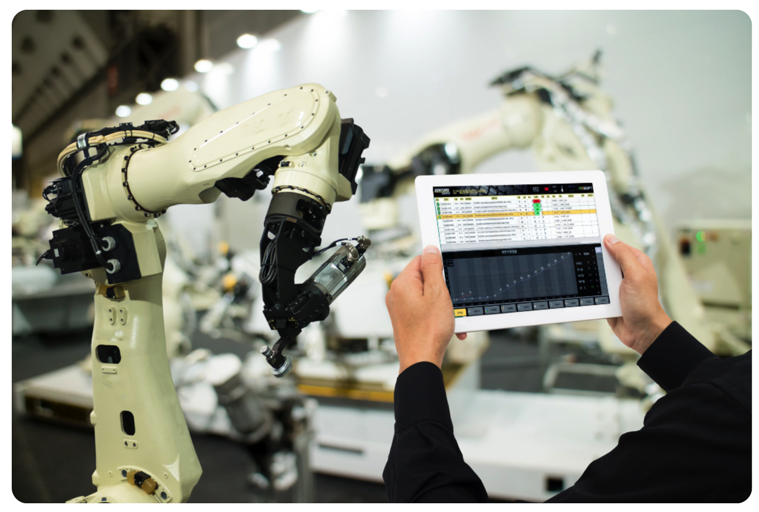

Establish efficient and three-dimensional production management mode

The multi-level production kanban board enables the management to grasp the production situation in real time

The flow of on-site materials is transparent, reducing material accumulation and reducing the number of on-site materials

Machine tool availability and utilization analysis

Machine tool history information review

Machining workpiece information

Machine tool alarm and information collection, statistics