Realize multi-variety planning and scheduling based on limited capacity

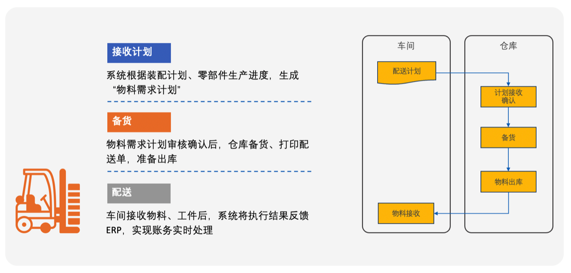

Implement production plan to pull material demand and drive product delivery logistics

Accurate planning and scheduling optimize the utilization of manufacturing resources

The production planning, execution and feedback form a business closed loop to realize lean management

Quality inspection data acquisition

Key parts information collection

Assembly quality information collection (process parameters, quality inspection data)

Quality data traceability

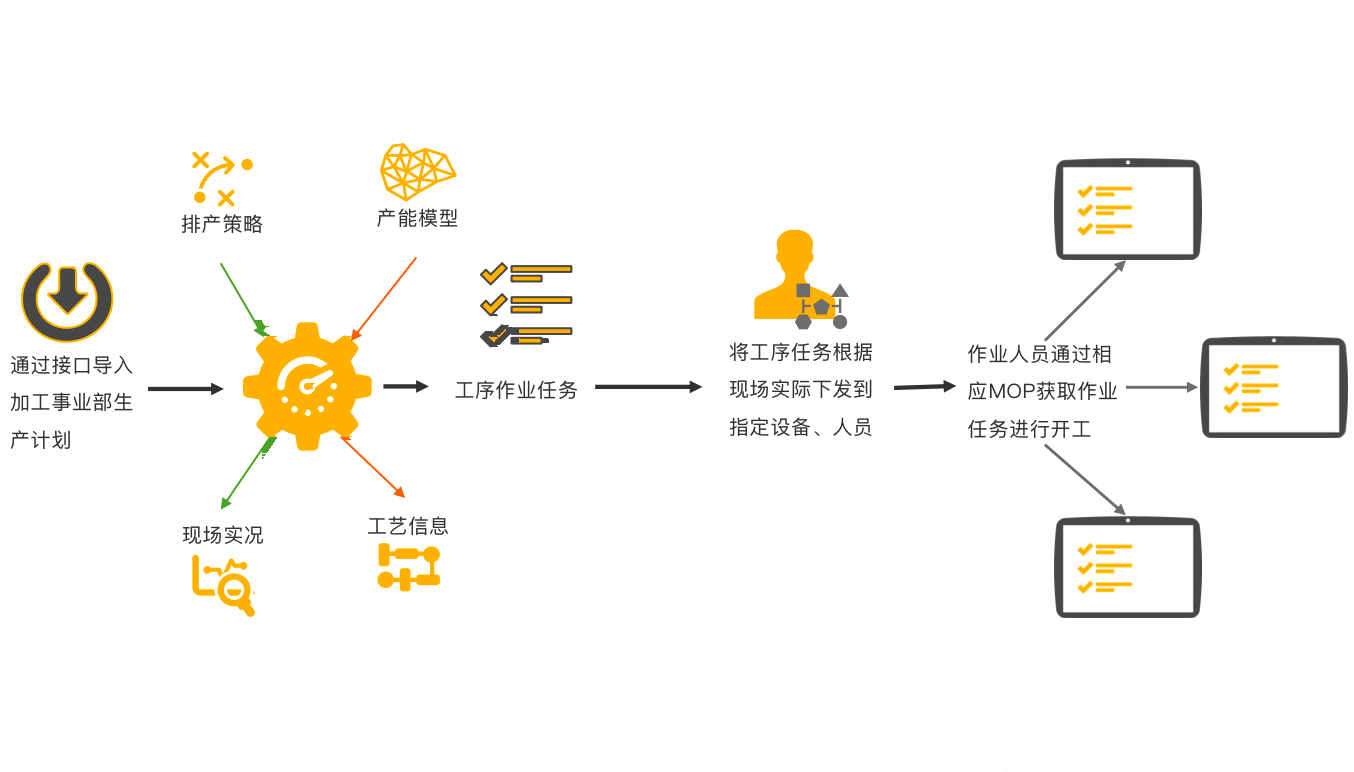

Intelligent algorithm to meet a variety of scheduling scenarios

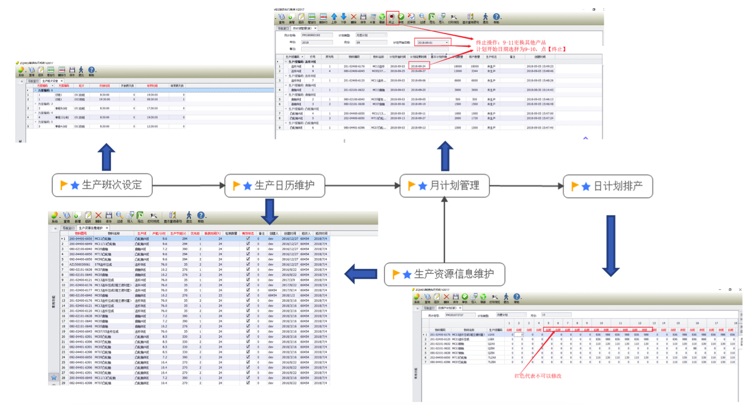

Multi-level planning and scheduling, direct production planning process

Panoramic resource and demand analysis, planning and demand balance control

Comprehensive control of project progress

Full control of planning system data chain

Scheduling constraints, policy deduction, execution closed-loop tracking

Collaborative group batch, multi-objective optimization, time slicing algorithm, multi-model analysis

Effectively reduce waste, return glue ratio, control material cost

Develop long-term plans based on the overall plan of capacity

Demand and supply linkage, supply chain coordination

Arrange the operation plan at different levels for workshop, process and equipment

According to the actual implementation of the plan, the global plan tracking and change control are realized

• Intelligent scheduling to achieve unified scheduling of multi-level plans, based on the homogeneity of production resources

• Make multi-level plans for body plant, frame plant and assembly plant

• Realize the step-by-step decomposition from the final assembly plan to the workshop and production plan of the body and frame factory

• Realize the collaborative linkage of supply chain production planning

Equipment static comprehensive management, complete the whole process control of equipment classification management - finding problems - joining the regular inspection plan - maintenance workers single pool

Improve the health of equipment, complete the new leap in equipment utilization under the precise planning schedule

Equipment interconnection, clear grasp of equipment running status, management work targeted

Build a complete equipment management knowledge system to form a knowledge base

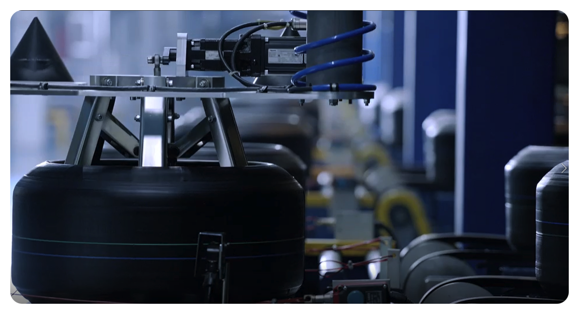

Intelligent picking of raw materials, workshop warehouse and finished product warehouse to reduce part picking errors

RFID WIP and circulation equipment tracking and tracing in production workshop

Through the production site visualization, improve the processing accuracy and timeliness of material supply

Quickly and conveniently generate material pulling information, real-time monitoring of material shortage, improve the timeliness of fed-material distribution

Through visual management, improve the production site management ability

Through production material tracking to achieve optimal management, improve material utilization efficiency

Achieve real-time performance statistics, strengthen production related assessment

Through the host computer, sensing system, transportation system, cache system, sorting system, storage unit and other processes

Reduce the information uncertainty caused by personnel participation

Complete the traceability system of material flow

Realize the accurate management of edge material

Efficient use and reduction of production space

Direct process of assigning and distributing production tasks

Real-time display of production information of each station or process of the production line

In the case of many types of aircraft, the technological process of different types of aircraft is well controlled

Parallel production, process/production line production beat matching each other, efficient coordination

• Material delivery and pull based on JIT/JIS/KANBAN/SPS mode

• Optimize time-sharing distribution and batch distribution to reduce the material backlog in the line-edge warehouse

• Effectively reduce the inventory pressure of daily warehouse and line edge warehouse

• Cooperate with suppliers and third-party libraries (3PL) to speed up the procurement and distribution process

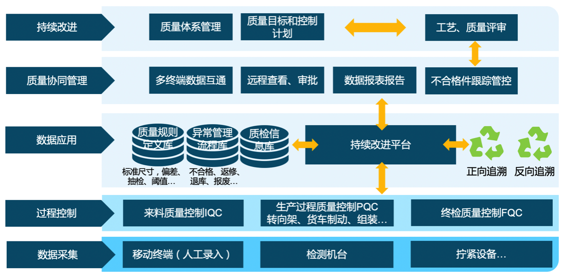

Rapid modeling, comparison, analysis, according to the actual needs of the enterprise for each dimension of quality analysis

Real-time quality related data acquisition, automatic generation of quality analysis report

The whole life cycle quality management of "raw material quality - production process quality - finished product quality - after-sales quality"

Job plan receiving and displaying

Product sequence and status on the assembly line

Equipment status information display and equipment spot inspection information maintenance

Material bar code acquisition

Lack of material or waste ANDON alarm

Station operator information collection

Strengthen process quality control, automatic correlation and judgment of quality information

Strengthen process quality early warning, monitor production parameters and process deviation, effectively avoid the spread of quality problems

Enhance the ability of quality traceability, quickly and accurately carry out the whole process of quality traceability

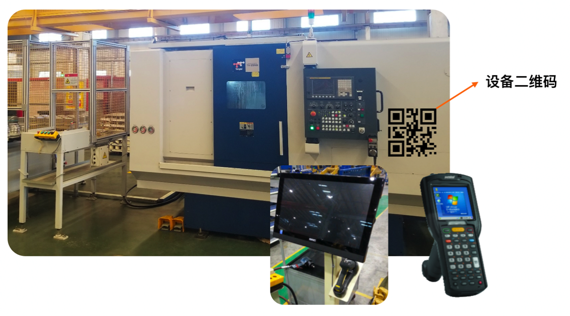

Establish industry equipment interface standards

Loosely coupled interface management pattern

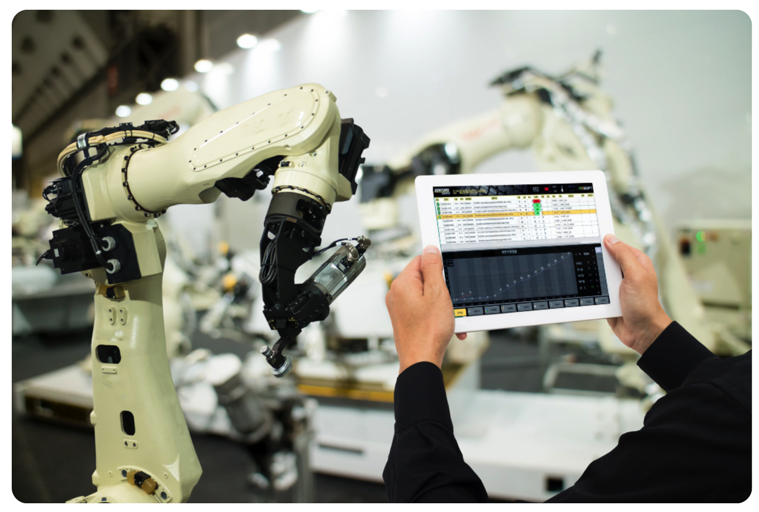

Efficiently control and monitor equipment running status

Complete the "health portrait" of the equipment.

Improve equipment utilization, ensure production plan and quality stability

Overall quality management, whole process quality data collection and traceability

Visualization and closed-loop control of quality event processing

Provide accurate data for managers to make decisions, improve production efficiency and product quality

• Networked group control of equipment to improve equipment efficiency: automatic instruction delivery, real-time state monitoring, process anti-error control, quality trend early warning, fault intelligent diagnosis

• Digital equipment mirror model: KPI system, get KPI indicators of equipment and make statistical analysis

• Adapt to a variety of device interface protocols and data source types

• Energy consumption statistics, cost analysis; Scientific prediction and optimization of indicators

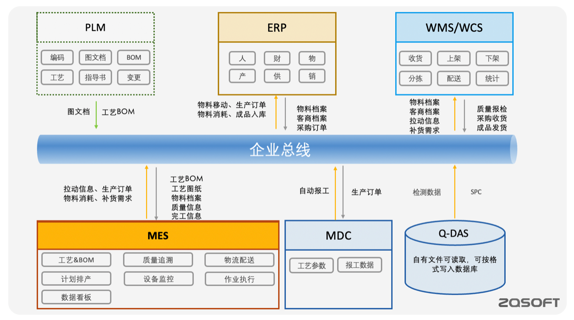

Improve the speed of business response, improve the collaboration relationship between businesses, and prevent non-compliance transactions

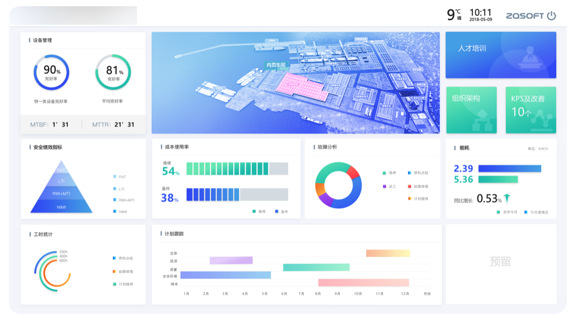

Establish efficient and three-dimensional production management mode

The multi-level production kanban board enables the management to grasp the production situation in real time

The flow of on-site materials is transparent, reducing material accumulation and reducing the number of on-site materials

ERP plan receiving and maintenance

Prepare production plan for assembly line and processing line according to resource constraints and configurations

Plan issuance and release

Production plan change management (order insertion, change handling)

Production plan query and export

ERP return on completion

Equipment abnormal rapid response, shorten production stagnation and waiting time

Improve the pertinence of equipment maintenance and reduce the cost of repair and maintenance

Improve equipment energy consumption management level, reduce production energy consumption

Detect the digital twin of the equipment and complete the integration of equipment data and experimental data

It solves difficulties such as multiple report styles and cumbersome management, and opens up business flow and data flow

Data structure, knowledge accumulation, tracking, analysis, speed up research and development efficiency

Help innovation research and development, improve the core competitiveness of products

Comprehensive control of equipment asset maintenance and spot inspection

Real-time acquisition of on-site production equipment data, graphical display

Get the production quantity and online processing status of each equipment in real time

Equipment failure real-time display, maintenance personnel timely grasp, fast processing

• Realize the data collection of vehicle point information and reflect the production status of the vehicle in real time

• Realize the digitization of regional location, inventory quantity and status information of WIP in workshop

• Data collection of the four major workshops and the inspection process, and the construction of complete vehicle files

• Realize multi-organization and remote unified control, and direct management instructions to the site

Machine tool availability and utilization analysis

Machine tool history information review

Machining workpiece information

Machine tool alarm and information collection, statistics

Assembly process personnel, products, assembly parts, assembly quality, assembly equipment processing parameters, equipment status, testing equipment, testing data

Data acquisition mode: bar code, RFID, equipment PLC interface, etc

Data statistics based on production process

Lean production related KPI index analysis: efficiency, output, quality, equipment

Realize the people-centered digital workshop management

Improve production site transparency, feedback speed, work efficiency

To achieve a high degree of unity of executive and personnel performance

Make enterprises pay more attention to HSE

Production monitoring and performance analysis

Capacity load assessment and process deviation monitoring

Process transparency and manufacturing decision support

Production process coordination and exception handling integrated management

• ANDON system, station abnormal information large screen, SMS real-time transfer relevant responsible person

• Electronic vehicle process quality inspection data collection and analysis, easy to find and analyze defects in the process

• Establish the definition of quality standards in line with industry standards and maintain the quality control plan

• Incoming material quality inspection data collection and quality judgment, realize the mutual traceability of the vehicle and key materials